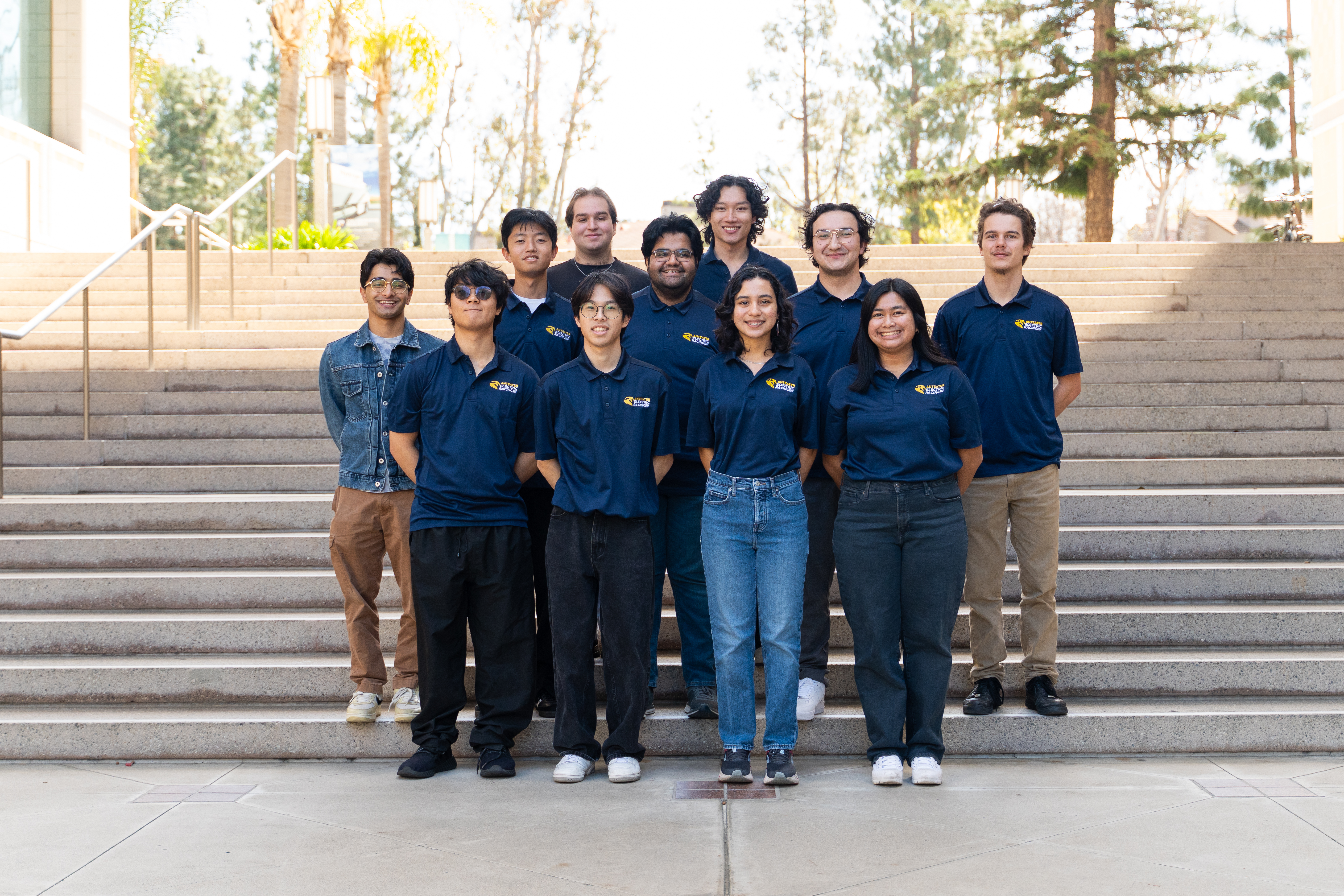

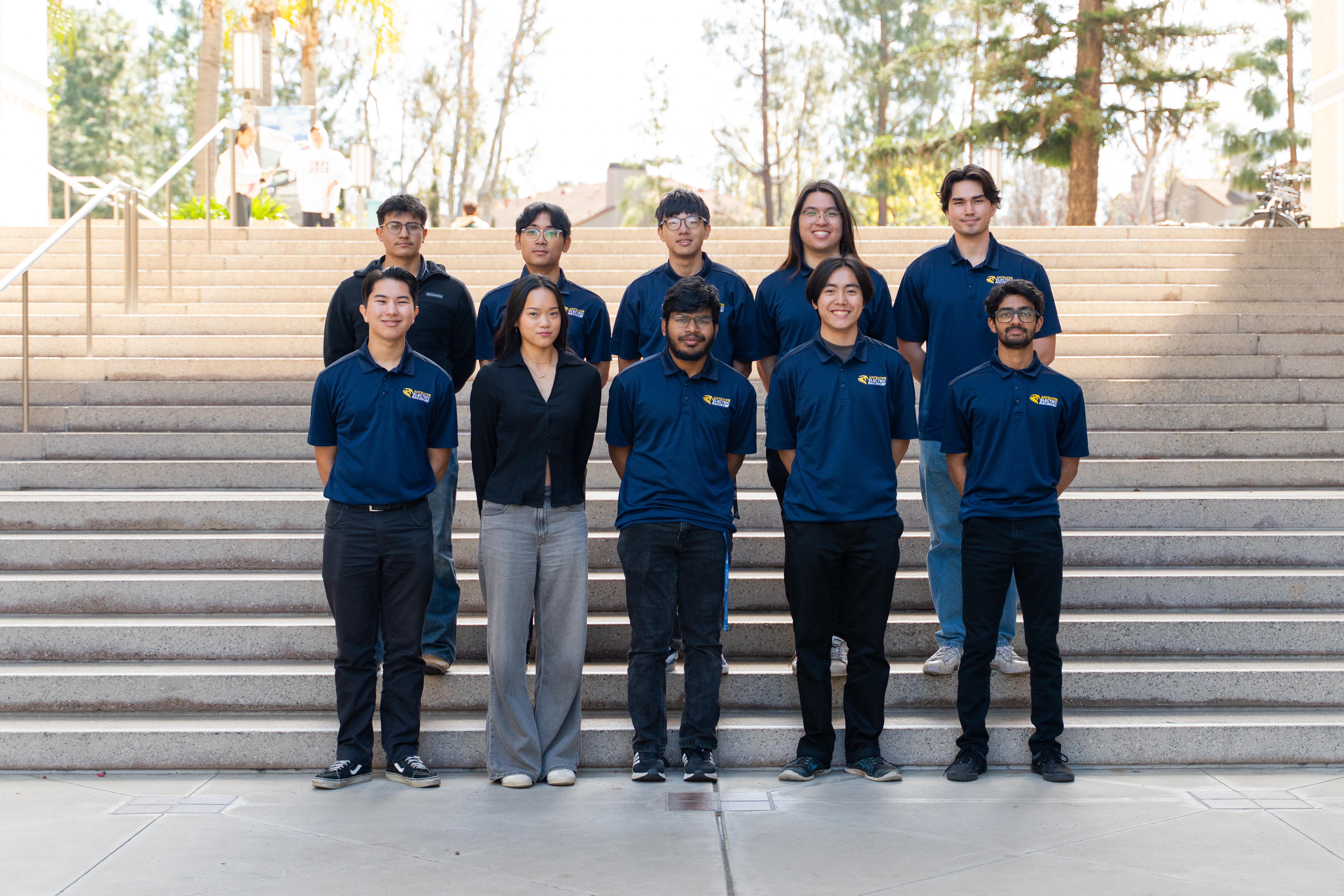

OUR SUBTEAMS

Specialized Engineering Groups Working Together

UCI Racing combines multiple disciplines, uniting students from various fields to design, build, and race a high-performance electric car. Each subteam plays a crucial role in our success, focusing on specific aspects of the vehicle's development and team operations.

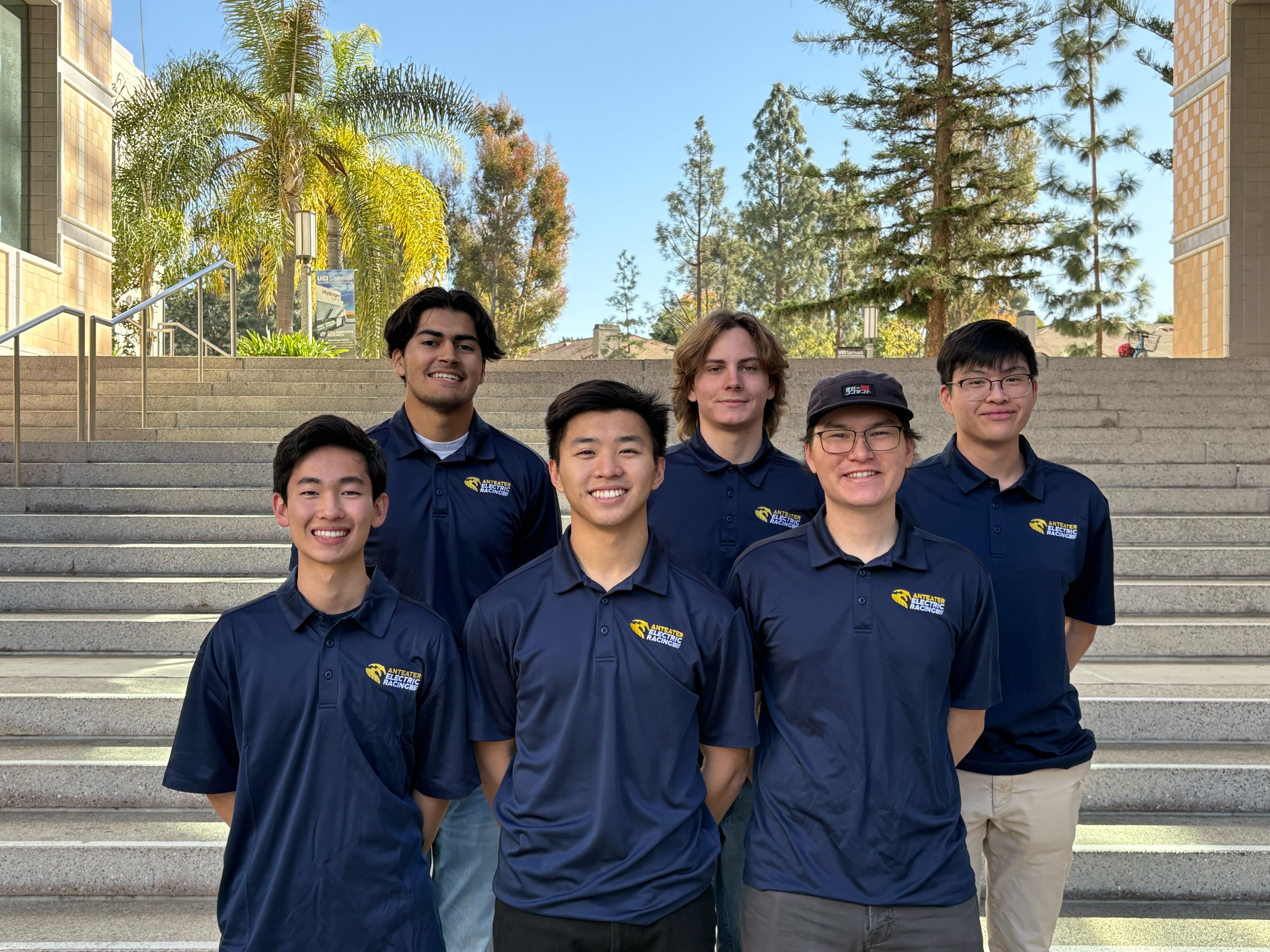

SUBTEAM DETAILS

Accumulator

The Accumulator subteam develops the physical housing, thermal solution, and the wiring for the energy storage system (ESS) that powers the vehicle from the cell level up. This team also designs and manufactures a specialized hand cart to lift the battery into the chassis of the vehicle.

Aerodynamics

The Aerodynamics subteam is responsible for the designing, manufacturing, testing and documentation of the body for the UCI electric racecar. The subteam is also responsible for the aerodynamic behavior of the vehicle, performing CFD analysis using programs such as SolidWorks and Flow Simulation.

Chassis

The Chassis subteam's mission is to engineer a design that balances minimal weight with exceptional structural integrity, ensuring precise component mounting through strategic triangulation. The chassis is the foundational structural framework of the vehicle, providing critical mounting points for suspension, powertrain, battery systems, and other key components.

Electronics

The Electronics subteam is responsible for designing, implementing, and optimizing the electrical systems of the vehicle. This includes managing high-voltage power distribution and low-voltage controls to ensure efficient and reliable operation of an electric race car. The team also focuses on integrating safety systems and ensuring compliance with competition regulations.

Embedded

The Embedded subteam is responsible for all the software and firmware development on the car. Embedded members will be using various microcontrollers to collect data from across the car, control the motor output and ensure that the car is safely and properly functioning. The embedded team will also be designing a system to wirelessly send and display diagnostic data for other teams to use.

Ergonomics

The Ergonomics subteam is responsible for the design, manufacturing, testing, and complete documentation of the EV's brake system, pedal assemblies, driver seat, seatbelt harness, and steering system. This subsystem's assembly designs promote functionality, driver safety, ergonomics, conditions, and ensure the driver and all engineers are aware of various vehicle inputs and ease of serviceability. Importantly, Ergonomics is responsible for driver safety in all outputs.

Operations and Outreach

The Operations and Outreach subteam is responsible for ensuring that the technical and non-technical aspects of the project are well-coordinated, enabling the engineering teams to focus on designing and building the car. Their work is essential for the successful development and competition of the FSAE car. This team also manages the project’s exposure through social media, project website, and networking.

Powertrain

The Powertrain subteam manages the driveline system, which is composed of a DC brushless motor, motor controller, differential, and axles. The subteam also designs and builds the motor controller apparatus to monitor and safely supply the motors with energy from the battery system.

Suspension

The Suspension subteam is responsible for designing not only a reliable system but a system tolerable within all dynamic scenarios. Components include control arms, rocker arms, wheel uprights and many others.

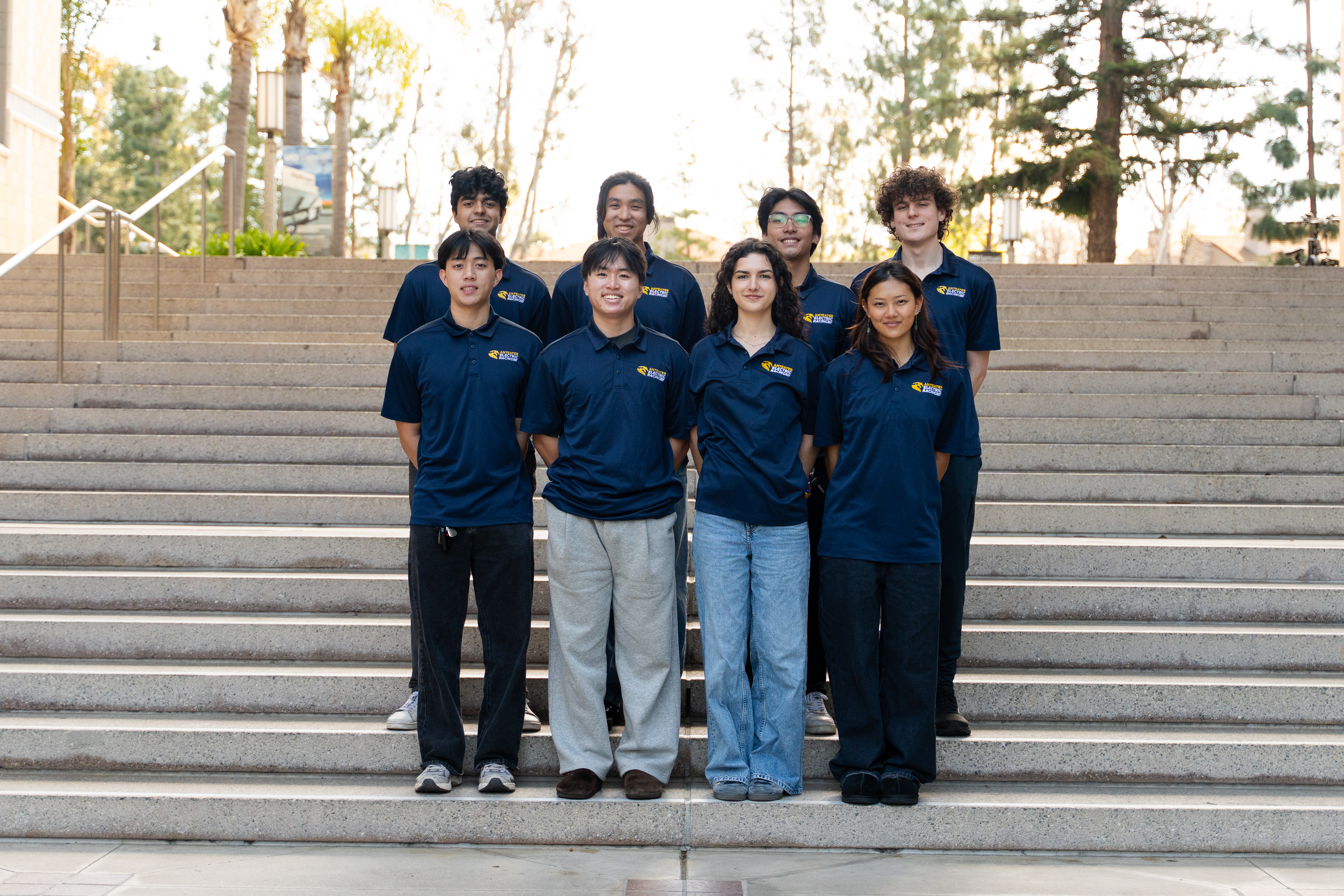

JOIN OUR TEAM

Whether you're interested in engineering, business, or project management, there's a place for you on our team. Join us in pushing the boundaries of electric vehicle technology!